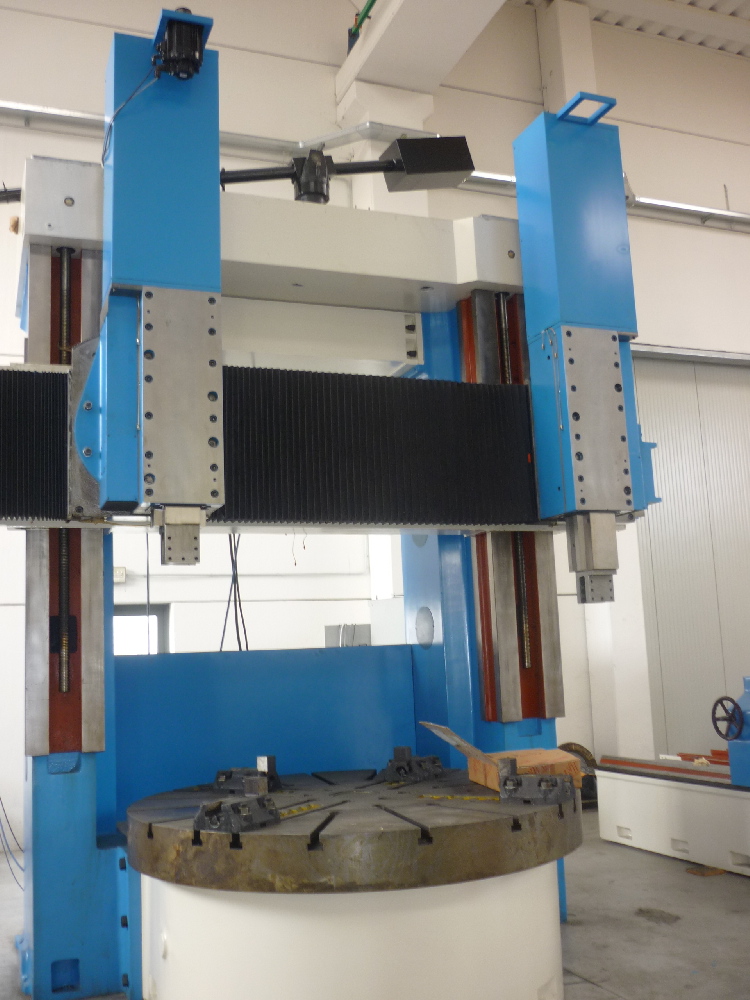

VERTICAL LATHE 2700 CNC -TFM

lathe vertical - Used

CNC-TFM

06207

MACHINE DESCRIPTION

Vertical lathe double column CNC with accurate positioning system and table clamping which enable, besides traditional turning operation, also drilling operation and tapping as well as linear milling; ideal for machining of rings, flanges, valve bodies ecc., so all pieces that required turning, drilling and possible tapping operations, after positioning over table.

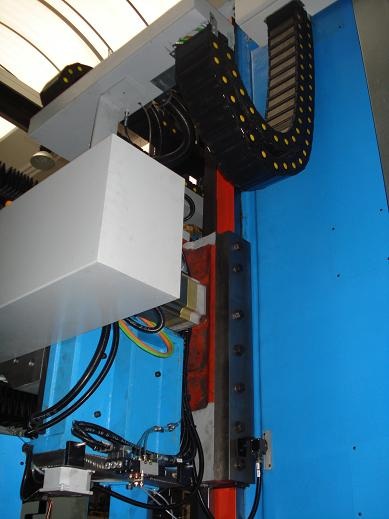

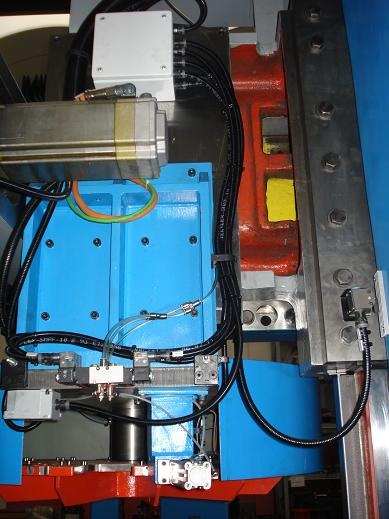

Machine is equipped with basement, where is seated table diameter 2.500 mm. and gear change box, and side column wich supports the crossrail. on crossrail operates a carriage RAM moved by ballscrew 50 P 10 with preloaded ballscrew with 5 ball revolutions, with a tool magazine 12 positions with automatic tool change.

Toolholder clamping is hydraulic; Toll magazine is able to allow toolholder for turning milling an tapping (taper ISO 50).

So it is possible to do every kind of turning operation, internal ed esternal, conic or cylindric; The powered RAM (motor power Kw 17) is able to make drilling machining and tapping with bore capacity 70 mm, by means of accuracy positioning system and table clamping.

Electric machine board is made with components mainly of Siemens brand, all electric motors and electronics that controls are new manufactured and guaranteed, as usual, by the manufacturer. Electric device and electronics are controlled by FAGOR 8055 or ECS 4802 (upon requirement is possible to put another CNC).

Lubrication and hydraulic movement of machine are possible by means of hydraulic device equiped with pump, electrovalves and other accessories of important italian brand (ILC, Camozzi, Duplomatic ecc.) which ensure efficiency and durability .

The machine is equiped with safety enclosure fitted with locks assisted by safety, as well as Integrated chip conveyor

TECHNICAL DETAILS:

Max turning diameter 2.630 mm.

Table diameter 2.500 mm.

Max load 15 ton.

Max working height 1.900 mm.

Table rotation 1,24-120 g/min.

No. of standard range 3 (hydraulic gear change)

Max RAM stroke:

- horizontal 1.750 mm.

- vertical 1.200 mm.

Max drilling diameter 70 mm.

Spindle motor power 57 Kw.

Drilling motor power 17 Kw.

Crossrail vertical stroke 1.600 mm

Machine weight 40 ton. ca.

Size (lenght x width x height) 4.800x5.100x5.200 mm. ca.

MACHINE RETROFITTED

06207

MACHINE DESCRIPTION

Vertical lathe double column CNC with accurate positioning system and table clamping which enable, besides traditional turning operation, also drilling operation and tapping as well as linear milling; ideal for machining of rings, flanges, valve bodies ecc., so all pieces that required turning, drilling and possible tapping operations, after positioning over table.

Machine is equipped with basement, where is seated table diameter 2.500 mm. and gear change box, and side column wich supports the crossrail. on crossrail operates a carriage RAM moved by ballscrew 50 P 10 with preloaded ballscrew with 5 ball revolutions, with a tool magazine 12 positions with automatic tool change.

Toolholder clamping is hydraulic; Toll magazine is able to allow toolholder for turning milling an tapping (taper ISO 50).

So it is possible to do every kind of turning operation, internal ed esternal, conic or cylindric; The powered RAM (motor power Kw 17) is able to make drilling machining and tapping with bore capacity 70 mm, by means of accuracy positioning system and table clamping.

Electric machine board is made with components mainly of Siemens brand, all electric motors and electronics that controls are new manufactured and guaranteed, as usual, by the manufacturer. Electric device and electronics are controlled by FAGOR 8055 or ECS 4802 (upon requirement is possible to put another CNC).

Lubrication and hydraulic movement of machine are possible by means of hydraulic device equiped with pump, electrovalves and other accessories of important italian brand (ILC, Camozzi, Duplomatic ecc.) which ensure efficiency and durability .

The machine is equiped with safety enclosure fitted with locks assisted by safety, as well as Integrated chip conveyor

TECHNICAL DETAILS:

Max turning diameter 2.630 mm.

Table diameter 2.500 mm.

Max load 15 ton.

Max working height 1.900 mm.

Table rotation 1,24-120 g/min.

No. of standard range 3 (hydraulic gear change)

Max RAM stroke:

- horizontal 1.750 mm.

- vertical 1.200 mm.

Max drilling diameter 70 mm.

Spindle motor power 57 Kw.

Drilling motor power 17 Kw.

Crossrail vertical stroke 1.600 mm

Machine weight 40 ton. ca.

Size (lenght x width x height) 4.800x5.100x5.200 mm. ca.

MACHINE RETROFITTED

FILL OUT OUR FORM FOR MORE INFORMATION

Potrebbero interessarti

.jpeg)

LATHE SAMU-TITAN RST 32 CNC

CNC-TFM

09411

VERTICAL

CNC SIMENS SINUMERIK

Max turning diameter mm 3300

Table diameter mm 3000

Max load...

09411

VERTICAL

CNC SIMENS SINUMERIK

Max turning diameter mm 3300

Table diameter mm 3000

Max load...

VERTICAL LATHE RADAR MOD- RAL-20M

CNC-TFM

09902

C AXIS and LIVE TOOLS

CNC FANUC Oi-TD

CAPACITY:

Table diameter mm 2000

Max swing diameter mm...

09902

C AXIS and LIVE TOOLS

CNC FANUC Oi-TD

CAPACITY:

Table diameter mm 2000

Max swing diameter mm...

LATHE CNC CAMU MM 10.000

CNC-TFM

09377

CNC FAGOR 8055

DOUBLE RAM

Turning Left Ram

ISO 50 right Ram

C-AXIS

Turning diameter mm from 3000...

09377

CNC FAGOR 8055

DOUBLE RAM

Turning Left Ram

ISO 50 right Ram

C-AXIS

Turning diameter mm from 3000...

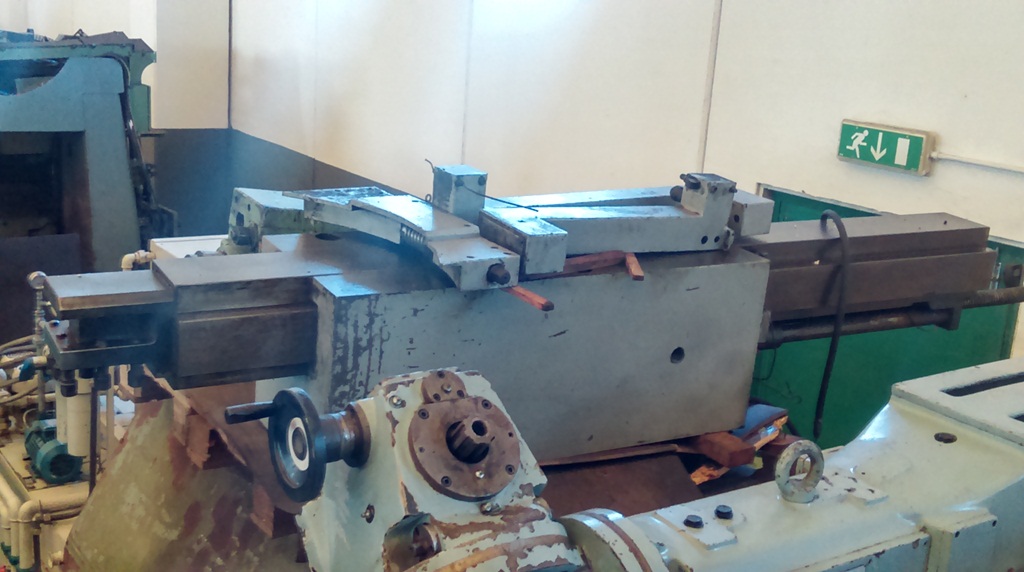

RAM FOR VERTICAL LATHE TITAN

VERTICAL TURNING LATHE LV 25 B

CNC-TFM

06674

Max turning diamater: 2.500 mm

Faceplate diameter: 2.250 mm

Load capacity: 16 Ton.

Max turning...

06674

Max turning diamater: 2.500 mm

Faceplate diameter: 2.250 mm

Load capacity: 16 Ton.

Max turning...

X

Invia tramite e-mail

X

Scarica PDF

Enter your email address to receive a link to download the PDF

Per poter procedere, la prima volta devi inserire i Tuoi dati