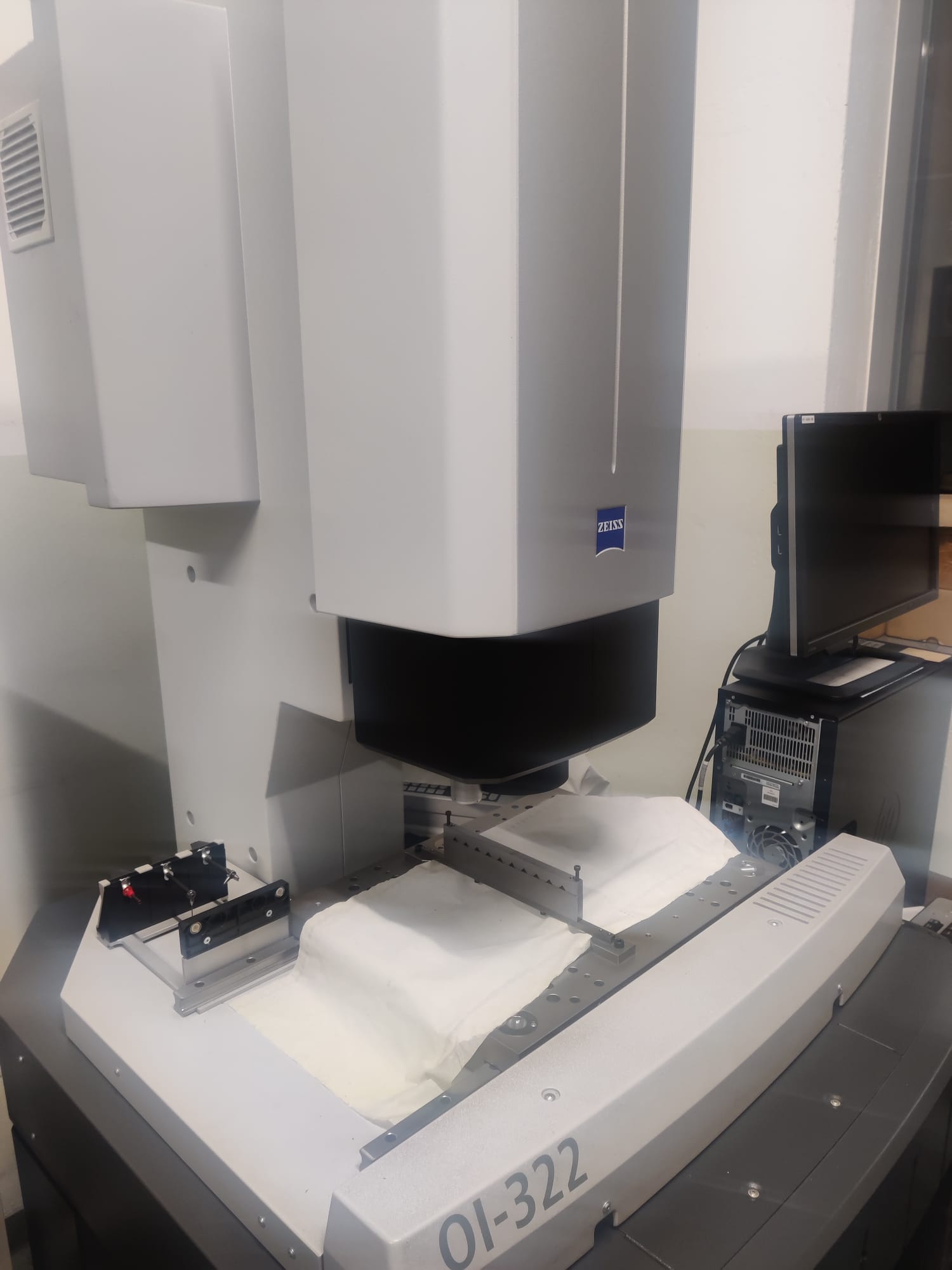

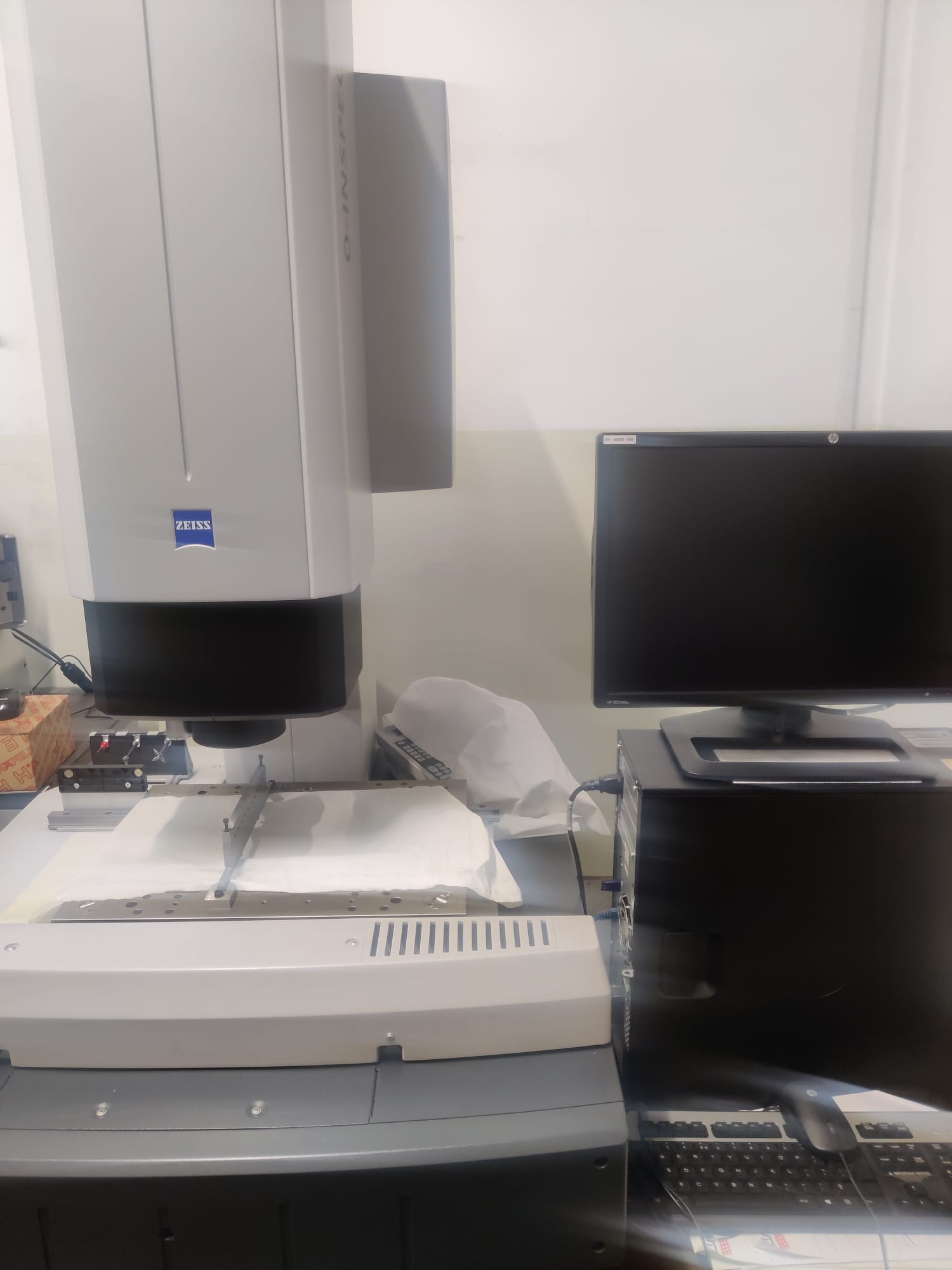

MEASURING ZEISS MOD. O-INSPECT 322

Metrology

measuring machines - Used

ZEISS

09330

MACHINE TECHNICAL DATA

Useful measuring range:

X= 300mm, Y= 200mm, Z=200mm

Maximum Permitted Errors "MPE" (Max Permissible Error, according to standard 150 10360-2):

With Vast XXT contact probe

MPEE XN = 1.6 + L/150 pm (L In mm)

MPEE XY = 1,9 + U150 pm (L ih mm)

3D MPEE = 2.4 + U150 pm (L in mm)

MPE P (Measuring Head) 2.4 pmi

With Discovery zoom lens

MPEE 1D (OT) = 1.6 + U200 pm (L in mm)

MPEE 2D (OT) = 1.9 + U150 pm (L in mm)

Environmental conditions in which the Maximum Permitted Errors are guaranteed:

Temperature 18°...22°

Gradient hour 1°C/h

Gradient day 2°C/day

Gradient meter 1°C/m

Relative humidity 40% to 70%

Operating conditions:

Temperature from 17°C to 35°C

Machine loading:

Max piece weight 20 Kg

Maximum travel speed:

X/Y 300 mm/sec

Z 100 mm/sec

Accel. Vector 500 mm/sec2

OPERATING MACHINE CONFIGURATION

1) O-INSPECT 322 MACHINE:

"Microscope design" structure with 2D moving table

Table height without base approx. 300 mm

Optical scale resolution 0.2 pm

Integrated anti-vibration system

Standard control panel

Calibration ball dia. = 25mm

Calibration ring dia. = 16mm

Scanning-Control (ISC): management of "Discovery" optical sensor and contact measuring head

Vast xxt on a single software basis

Star probe kit TL1, 8 pcs. (code 626103-9031-000 for TL1)

2) SENSORS:

-Zeiss "Discovery" optical sensor with 12x zoom equiped with:

Integrated HD Camera

12x Zoom Zeiss Discovery

Ring in two-tone light (red/blue)

MiniRing in two-tone light (red/blue)

Coaxial light

Transmitted light

Calypso software option for image analysis

Optical measurement for elements: point, circle, ellipse, line, 2D profile

Analysis of the black and white image with dynamic procedure and automatic correlation of the adjustable illumination level

Possibility of point to point measurement and continuous scanning with optical sensor

-Vast xxt passive CONTINUOUS SCAN Zeiss measurement sensor for "Point to point" and "Continuous scan" measurements, complete with module for managing probes with length from 30 to 125 mm and plate with electromagnetic coupling

3) CALYPSO program:

Graphically developed CAD heart measuring program for measurements on prismatic workpieces.

Ease of use due to control plan based procedure.

Full graphical support for visualization of measurement strategies and input data.

Reduced use of the keyboard and low margin of error thanks to the automatic recognition of the measured elements and the automatic generation of CNC measuring programs.

Optimization of the measurement time thanks to the variable measurement plans, by selecting the elements involved in the cycle.

Variable presentation of results with easy integration of graphical parts.

Complete multimedia support, for example for illustrating workpiece fixtures and probe configurations for the start of the CNC cycle.

Possibility of importing 3D CAD drawings in SAT or SAB format for optimal graphic representation on screen and for off-line programming of CNC measuring cycles (optional CAD interfaces).

4) Dell Precision T 3500 WORKSTATION:

Intel Xeon Quad Core Processor W3530 (2.80GHz,4.83T/s,8MB,4C)

Operating System: Windows 7 Ultimate 64 bit MUI (Multilanguage)

Graphics Card: NVIDIA Quadro 2000, 1GB

RAM memory: 6 GB RAM 1333 MHz ECC—UDIMM

Additional network card : Gigabit Ethernet PCI-E 10/100/1000

Hard Disk: 2x500 GB SATA II, 7200 RPM ,RAID1, 8MB DataBurst Cache

DVD drive: 16XDVD +/- RW Combi drive

Mouse: Dell laser 6 Button USB Scroll Optical MOUSE

Keyboard: international in Italian language

Software package: Acronis True Image Home 2012 - Part number 494-892

Dongle: Part number 000000-0475-671

Monitor : Dell Led Professional 24" P2412H- Code 533-179

Printer: HP Officejet PRO 8100 mod. CM752A - Cod ce 543-968

USED MACHINE

YEAR 2013

09330

MACHINE TECHNICAL DATA

Useful measuring range:

X= 300mm, Y= 200mm, Z=200mm

Maximum Permitted Errors "MPE" (Max Permissible Error, according to standard 150 10360-2):

With Vast XXT contact probe

MPEE XN = 1.6 + L/150 pm (L In mm)

MPEE XY = 1,9 + U150 pm (L ih mm)

3D MPEE = 2.4 + U150 pm (L in mm)

MPE P (Measuring Head) 2.4 pmi

With Discovery zoom lens

MPEE 1D (OT) = 1.6 + U200 pm (L in mm)

MPEE 2D (OT) = 1.9 + U150 pm (L in mm)

Environmental conditions in which the Maximum Permitted Errors are guaranteed:

Temperature 18°...22°

Gradient hour 1°C/h

Gradient day 2°C/day

Gradient meter 1°C/m

Relative humidity 40% to 70%

Operating conditions:

Temperature from 17°C to 35°C

Machine loading:

Max piece weight 20 Kg

Maximum travel speed:

X/Y 300 mm/sec

Z 100 mm/sec

Accel. Vector 500 mm/sec2

OPERATING MACHINE CONFIGURATION

1) O-INSPECT 322 MACHINE:

"Microscope design" structure with 2D moving table

Table height without base approx. 300 mm

Optical scale resolution 0.2 pm

Integrated anti-vibration system

Standard control panel

Calibration ball dia. = 25mm

Calibration ring dia. = 16mm

Scanning-Control (ISC): management of "Discovery" optical sensor and contact measuring head

Vast xxt on a single software basis

Star probe kit TL1, 8 pcs. (code 626103-9031-000 for TL1)

2) SENSORS:

-Zeiss "Discovery" optical sensor with 12x zoom equiped with:

Integrated HD Camera

12x Zoom Zeiss Discovery

Ring in two-tone light (red/blue)

MiniRing in two-tone light (red/blue)

Coaxial light

Transmitted light

Calypso software option for image analysis

Optical measurement for elements: point, circle, ellipse, line, 2D profile

Analysis of the black and white image with dynamic procedure and automatic correlation of the adjustable illumination level

Possibility of point to point measurement and continuous scanning with optical sensor

-Vast xxt passive CONTINUOUS SCAN Zeiss measurement sensor for "Point to point" and "Continuous scan" measurements, complete with module for managing probes with length from 30 to 125 mm and plate with electromagnetic coupling

3) CALYPSO program:

Graphically developed CAD heart measuring program for measurements on prismatic workpieces.

Ease of use due to control plan based procedure.

Full graphical support for visualization of measurement strategies and input data.

Reduced use of the keyboard and low margin of error thanks to the automatic recognition of the measured elements and the automatic generation of CNC measuring programs.

Optimization of the measurement time thanks to the variable measurement plans, by selecting the elements involved in the cycle.

Variable presentation of results with easy integration of graphical parts.

Complete multimedia support, for example for illustrating workpiece fixtures and probe configurations for the start of the CNC cycle.

Possibility of importing 3D CAD drawings in SAT or SAB format for optimal graphic representation on screen and for off-line programming of CNC measuring cycles (optional CAD interfaces).

4) Dell Precision T 3500 WORKSTATION:

Intel Xeon Quad Core Processor W3530 (2.80GHz,4.83T/s,8MB,4C)

Operating System: Windows 7 Ultimate 64 bit MUI (Multilanguage)

Graphics Card: NVIDIA Quadro 2000, 1GB

RAM memory: 6 GB RAM 1333 MHz ECC—UDIMM

Additional network card : Gigabit Ethernet PCI-E 10/100/1000

Hard Disk: 2x500 GB SATA II, 7200 RPM ,RAID1, 8MB DataBurst Cache

DVD drive: 16XDVD +/- RW Combi drive

Mouse: Dell laser 6 Button USB Scroll Optical MOUSE

Keyboard: international in Italian language

Software package: Acronis True Image Home 2012 - Part number 494-892

Dongle: Part number 000000-0475-671

Monitor : Dell Led Professional 24" P2412H- Code 533-179

Printer: HP Officejet PRO 8100 mod. CM752A - Cod ce 543-968

USED MACHINE

YEAR 2013

FILL OUT OUR FORM FOR MORE INFORMATION

Potrebbero interessarti

X

Invia tramite e-mail

X

Scarica PDF

Enter your email address to receive a link to download the PDF

Per poter procedere, la prima volta devi inserire i Tuoi dati