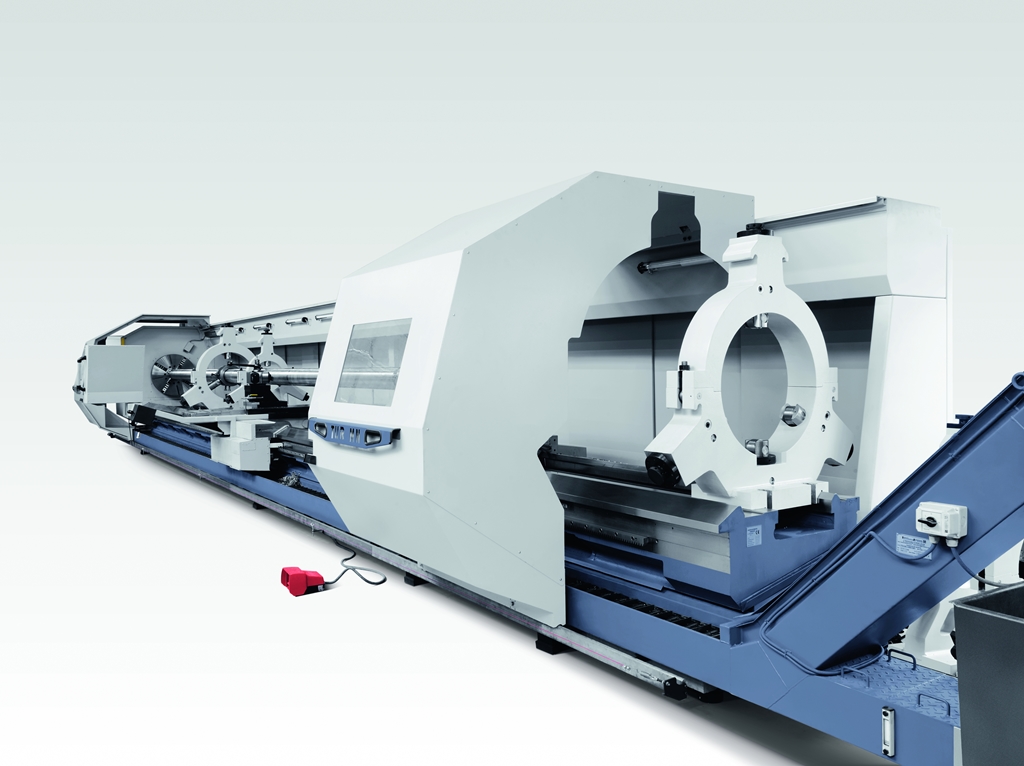

LATHE FAT TUR 1350 MN x 8000

Autoteaching

lathe cnc - Used

FAT

08638

FLAT BED AUTOMATIC

CAPACITY

Distance between centre mm 8000

Swing over bed mm 1550

Swing over carriage mm 1300

Max. load between centre kg 20.000 (without steadies)

SPINDLE

Speed range

Main motor power (S6) kW 75

Esecuzione standard

Spindle nose DIN55026 A2-15

Front bearing mm 250

Spindle bore mm 140

Speed range:

- I range 2-200 rpm

- II range 180-900 rpm

Max. torque Nm 8250

CARRIAGE

Cross travel X axis mm 750

Rapid Z axis m/min 8

Rapid X axis m/min 10

Cross force kN 25

Longitudinal force kN 35

Ball screw Z axis mm 80

Ball screw X axis mm 40

Carriage lenght mm 1150

Cross guideway width mm 366

HEAVY EXECUTION HYDRAULIC TAILSTOCK

Quill diameter mm 280

Quill taper MT6

Quill stroke mm 300

GENERAL

Bed width mm 1020

Tot machine lenght mm 11200

Width mm 3300

Height mm 2550

Weight kg 24800

STANDARD EQUIPMENT:

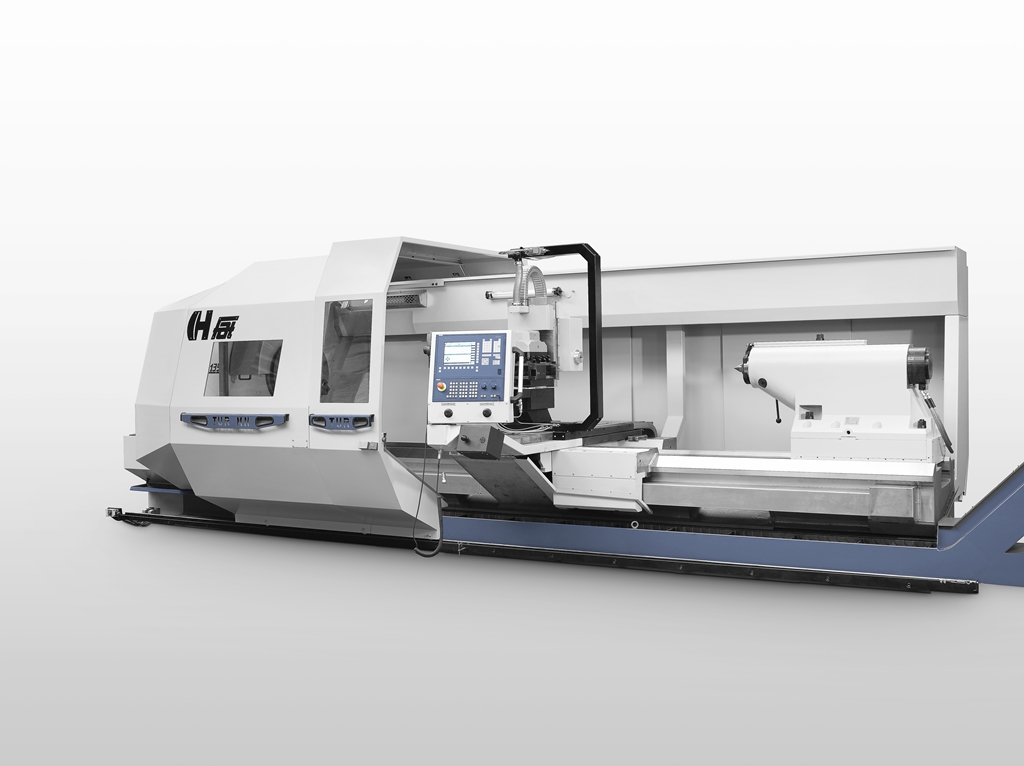

-CNC Siemens Sinumerik 840D SL

-Tensione elettrica 3x400 V

-Automatic programmable change 2-step gearbox

-Machine color RAL 7031/7044

-Tube lights in working area

-Hydraulic unit

-Complete coolant system

-One movable front door (connected to cross slide) and full back guard

-Tailstock with rapid clamping system to carriage

-Quil diameter mm 280

-Automatic lubrication system for spindle body

-Automatic lubrication system for carriage and slideway

-USB port, Ethernet connection on operator panel

-Absolute encoder

-One set manual user/ programming and maintenance in english language

-EC conformity

ACCESSORIES INCLUDED:

-Cnc Siemens Sinumerik 840D with display touchscreen 15''

-C axis positioning by main motor; with hydraulic brake– Positioning accuracy +/- 0,02degrees one spindle nose

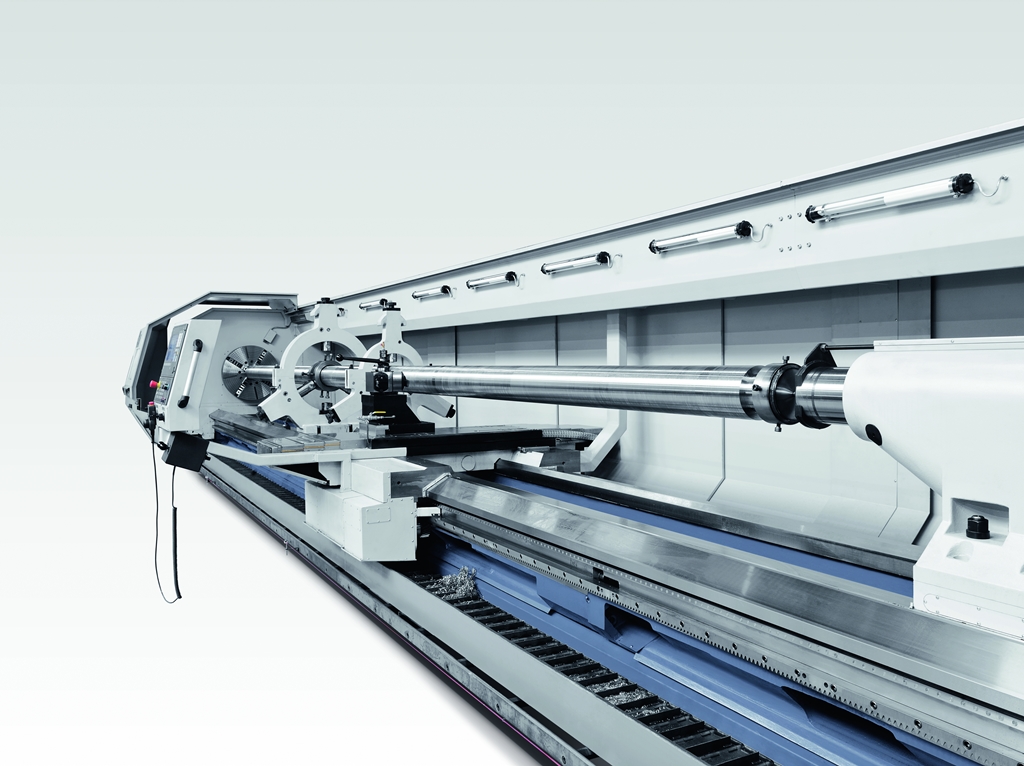

-Horizontal BI-DIRECTIONAL 4-position head turret Baruffaldi TAB 340, dovetail tool seat acc. to DIN 69 881 – formerly VDI 3425; nominal size 40, hydraulic clamping system; delivered without tool holders

-Linear scale pressurized X e Z

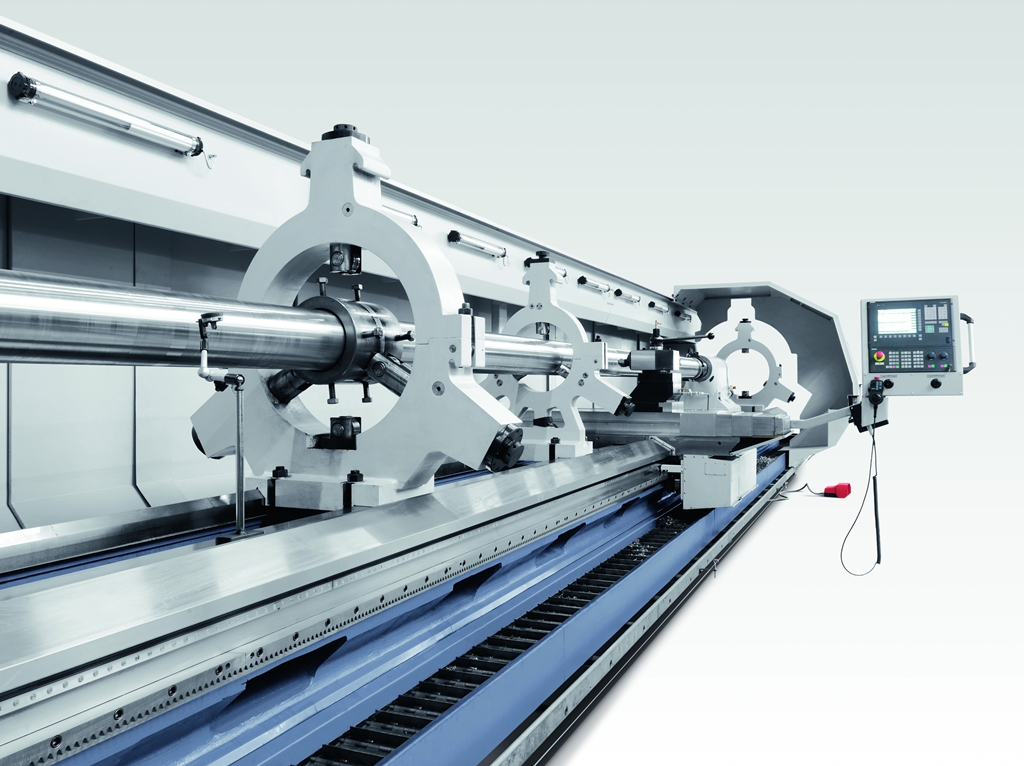

-Steady Rest with Roller Quills - Ø 50- 400

-Steady Rest with Roller Quills - Ø 380- 700

-High Pressure Pump for coolant system; max. 20 Bar; 1,7 kw; max. Q=50L/min

-Chip conveyor

-3 D Simulation Of Work Piece

-Real Time Simulation

-Additional Ethernet port inside electrical cabinet

NEW MACHINE COMING SOON

08638

FLAT BED AUTOMATIC

CAPACITY

Distance between centre mm 8000

Swing over bed mm 1550

Swing over carriage mm 1300

Max. load between centre kg 20.000 (without steadies)

SPINDLE

Speed range

Main motor power (S6) kW 75

Esecuzione standard

Spindle nose DIN55026 A2-15

Front bearing mm 250

Spindle bore mm 140

Speed range:

- I range 2-200 rpm

- II range 180-900 rpm

Max. torque Nm 8250

CARRIAGE

Cross travel X axis mm 750

Rapid Z axis m/min 8

Rapid X axis m/min 10

Cross force kN 25

Longitudinal force kN 35

Ball screw Z axis mm 80

Ball screw X axis mm 40

Carriage lenght mm 1150

Cross guideway width mm 366

HEAVY EXECUTION HYDRAULIC TAILSTOCK

Quill diameter mm 280

Quill taper MT6

Quill stroke mm 300

GENERAL

Bed width mm 1020

Tot machine lenght mm 11200

Width mm 3300

Height mm 2550

Weight kg 24800

STANDARD EQUIPMENT:

-CNC Siemens Sinumerik 840D SL

-Tensione elettrica 3x400 V

-Automatic programmable change 2-step gearbox

-Machine color RAL 7031/7044

-Tube lights in working area

-Hydraulic unit

-Complete coolant system

-One movable front door (connected to cross slide) and full back guard

-Tailstock with rapid clamping system to carriage

-Quil diameter mm 280

-Automatic lubrication system for spindle body

-Automatic lubrication system for carriage and slideway

-USB port, Ethernet connection on operator panel

-Absolute encoder

-One set manual user/ programming and maintenance in english language

-EC conformity

ACCESSORIES INCLUDED:

-Cnc Siemens Sinumerik 840D with display touchscreen 15''

-C axis positioning by main motor; with hydraulic brake– Positioning accuracy +/- 0,02degrees one spindle nose

-Horizontal BI-DIRECTIONAL 4-position head turret Baruffaldi TAB 340, dovetail tool seat acc. to DIN 69 881 – formerly VDI 3425; nominal size 40, hydraulic clamping system; delivered without tool holders

-Linear scale pressurized X e Z

-Steady Rest with Roller Quills - Ø 50- 400

-Steady Rest with Roller Quills - Ø 380- 700

-High Pressure Pump for coolant system; max. 20 Bar; 1,7 kw; max. Q=50L/min

-Chip conveyor

-3 D Simulation Of Work Piece

-Real Time Simulation

-Additional Ethernet port inside electrical cabinet

NEW MACHINE COMING SOON

FILL OUT OUR FORM FOR MORE INFORMATION

Potrebbero interessarti

LATHE SAFOP LEONARD 550NC 8500

FAT

07383

4 GUIDEWAYS

LIVE TOOLS

AXIS C

DOUBLE CARRIAGE WITH INDIPENDENT CONTROL

CNC ECS 2400

Height of...

07383

4 GUIDEWAYS

LIVE TOOLS

AXIS C

DOUBLE CARRIAGE WITH INDIPENDENT CONTROL

CNC ECS 2400

Height of...

SCREW MILLING MACHINE SAPORITI

FAT

07393

MOD. L 560 E S DOPPIA A CNC

WITH DOUBLE HEAD [FOR HIGH PRODUCTION OF SCREW]

7 AXIS

CNC AUTOMATA...

07393

MOD. L 560 E S DOPPIA A CNC

WITH DOUBLE HEAD [FOR HIGH PRODUCTION OF SCREW]

7 AXIS

CNC AUTOMATA...

LATHE SHENYANG SMTCL HTC80200

FAT

08840

CNC FANUC Oi-TC + remote handwheel

Max swing diameter over bed mm 1000

Max turning length 2000...

08840

CNC FANUC Oi-TC + remote handwheel

Max swing diameter over bed mm 1000

Max turning length 2000...

LATHE MAZAK INTEGREX 300II SY

FAT

09379

AXIS Y

SPINDLE/SUB-SPINDLE

LIVE TOOLS

CNC Mazatrol Fusion 640 MT

CAPACITY:

Max swing diameter mm...

09379

AXIS Y

SPINDLE/SUB-SPINDLE

LIVE TOOLS

CNC Mazatrol Fusion 640 MT

CAPACITY:

Max swing diameter mm...

LATHE ARIS MOD. SGN 1400

FAT

09901

4 GUIDES

CNC FAGOR 8055

Turning diameter under head mm 2200

Turning diameter on carriage mm...

09901

4 GUIDES

CNC FAGOR 8055

Turning diameter under head mm 2200

Turning diameter on carriage mm...

X

Invia tramite e-mail

X

Scarica PDF

Enter your email address to receive a link to download the PDF

Per poter procedere, la prima volta devi inserire i Tuoi dati